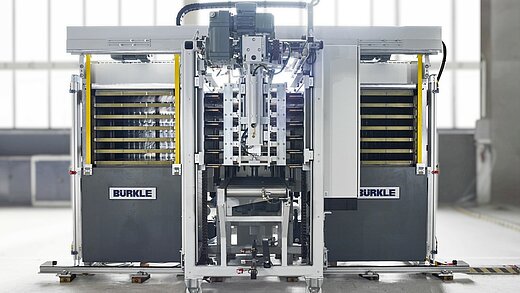

- Flexible and compact design to accommodate small/medium to high production requirements

- Stand alone or System Thermal oil heated lamination plants up to 400°C for special materials

- Manual or fully automatic loading/unloading systems

- Enclosed Vacuum Chamber allows significant specific pressure reduction cycles

- Vertical sliding door for very compact design

- Only one central piston guarantee even pressure distribution across the platen area

- Prismatic VEE guides system guarantee that all platens are parallel during pressing cycle

- Hot Press Heating Platens equipped with Spring Loaded Sliding Rails

- High temperature uniformity across the entire platen surface

- Thermal oil piping at the rear of the hot press for easier access and maintenance

- PC- System (HMI) Windows 7 Professional

- Operating and Observing System based on the Standard Software Intouch/ Wonderware (user-friendly, menu-driven)

- Diagnostic Tool for PC and PLC Software by BRSS (Bürkle Remote Service System)